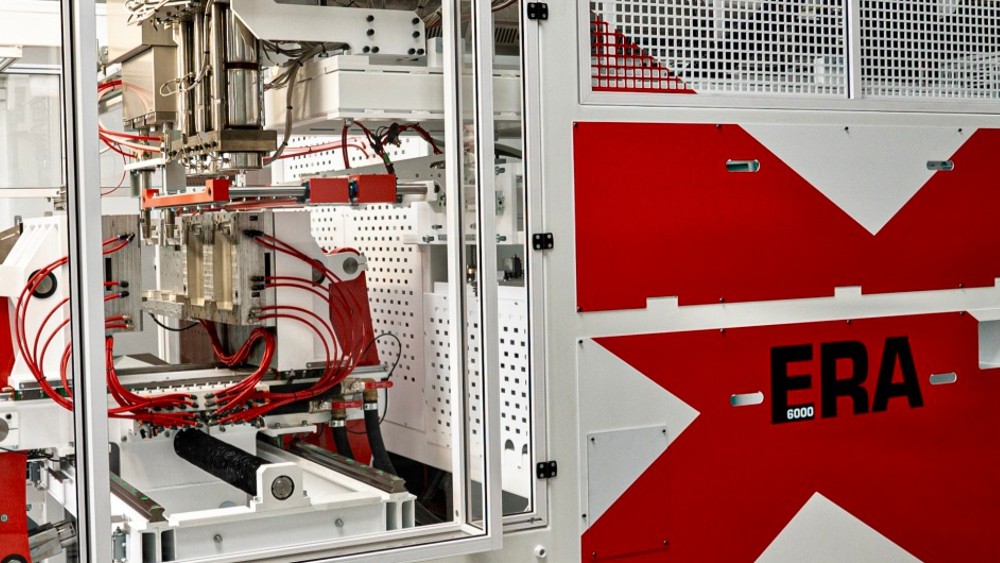

| Extrusion blow molding machines ERA2000 to ERA6000 are upper-blow molding machines used in plastics processing, for the automatic manufacture of thermoplastic containers by extrusion blow molding. The machine is composed of an extruder, a blow molding machine with one carriage, a station for automatic overmolding removal. All of it is placed inside a solid welded frame, with a complete cabin ensuring safety. The machines we offer to you are made of components of well-known global companies. All movements of the machine are carried out on linear bearings (induction hardened shafts and rails, guides and rolling bearing carriages – 100% spare parts). The machine is controlled using comprehensive automation of B&R (Austria). Temperature control, extruder operation, control of the blowing machine and machine diagnostics is performed using an advanced PLC with a touch panel. The machine is equipped with a station for automatic overmolding removal. The extruder’s drive – motor reducer NORD (Germany), with temperature-resistant seals and synthetic oil. Pneumatic drive of the machine is produced by METALWORK (Italy). Parison control – 100 adjustment points, servo motor drive. The carriage is moved with an electric drive – servo motor. Electric drive of blowing mandrels – servo motor. Device for mounting deburring machines used for automatic removal of overmolding. Device for removal of bottom overmolding of containers. Hot or cold knife for sleeve cutting. Heating system – cylinder cooling with adjustable fan power. User manual, CE declaration of conformity, 12 months of warranty. Starting and basic training in operating the machine. SELECTED COMPETITIVE ADVANTAGES: Machine motion control, all positions of the moving parts of the machine, extruder heating control – exceeded dangerous temperature and automatic shutdown of the machine, check of time of oil change in extruder gear, extruder operation time counter, forming machine cycle counter. |

Recent Comments